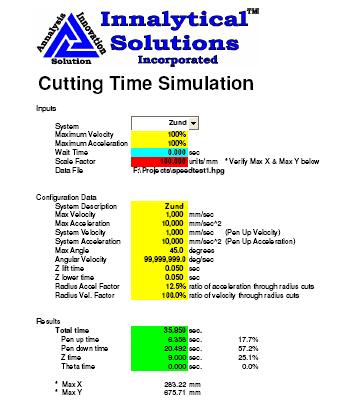

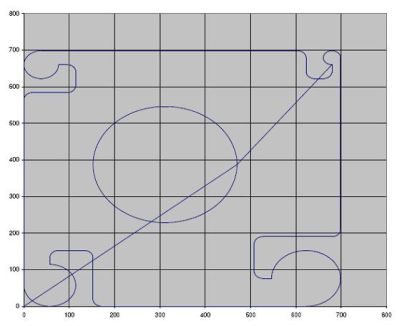

The challenge was to create an estimate of the time required to complete a programmed cutting cycle on a commercial finishing system. The system consisted of a cutting head mounted on a two axis gantry. The path was created using a graphical program and exported as an HPGL file. The primary concerns were achieving an error of less than 10% and ease of use.

The solution was to create an Excel spreadsheet to complete the calculations and macros to automate the process. The path data was created by importing the HPGL file and converting each line into the appropriate motion. (Arcs were converted into a series of small linear moves.) The spreadsheet calculated the time required for each move and generated a total cutting time.