Automated Assembly

Innalytical Solutions supports businesses that lack the staff or experience to complete assembly automation projects.

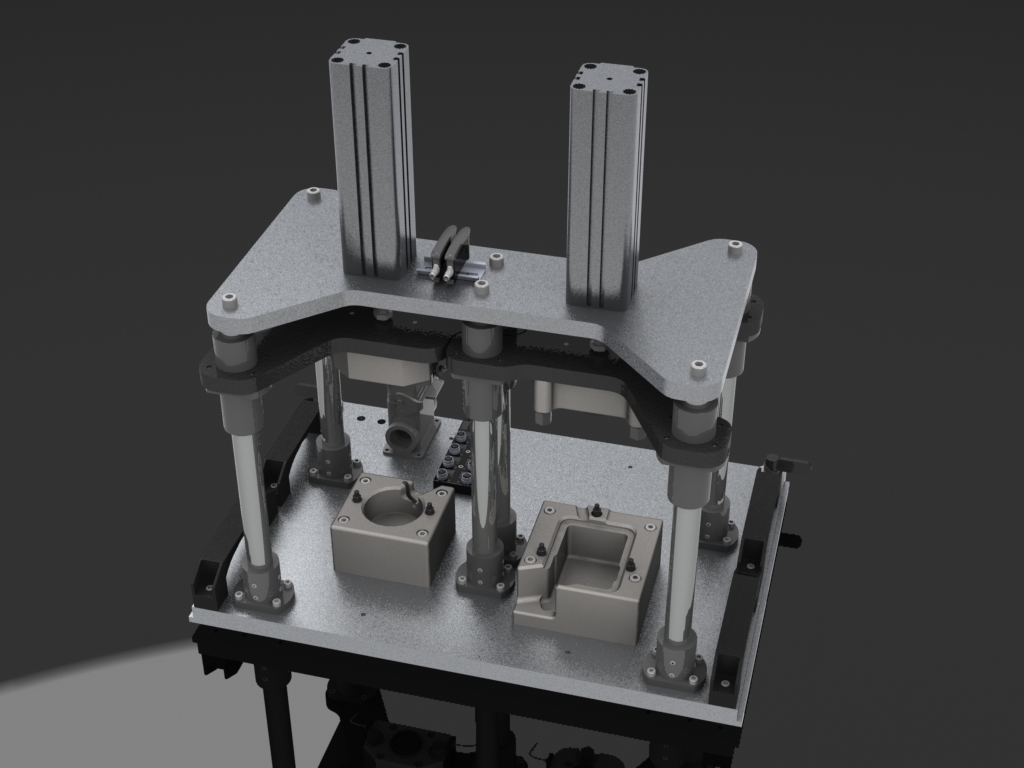

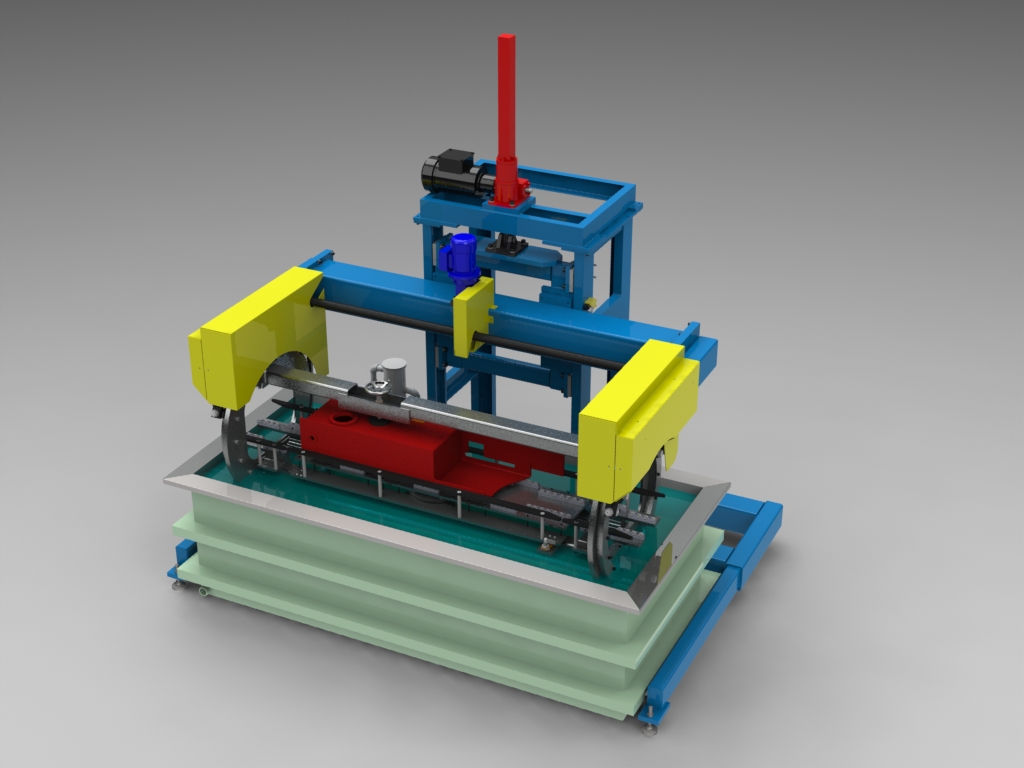

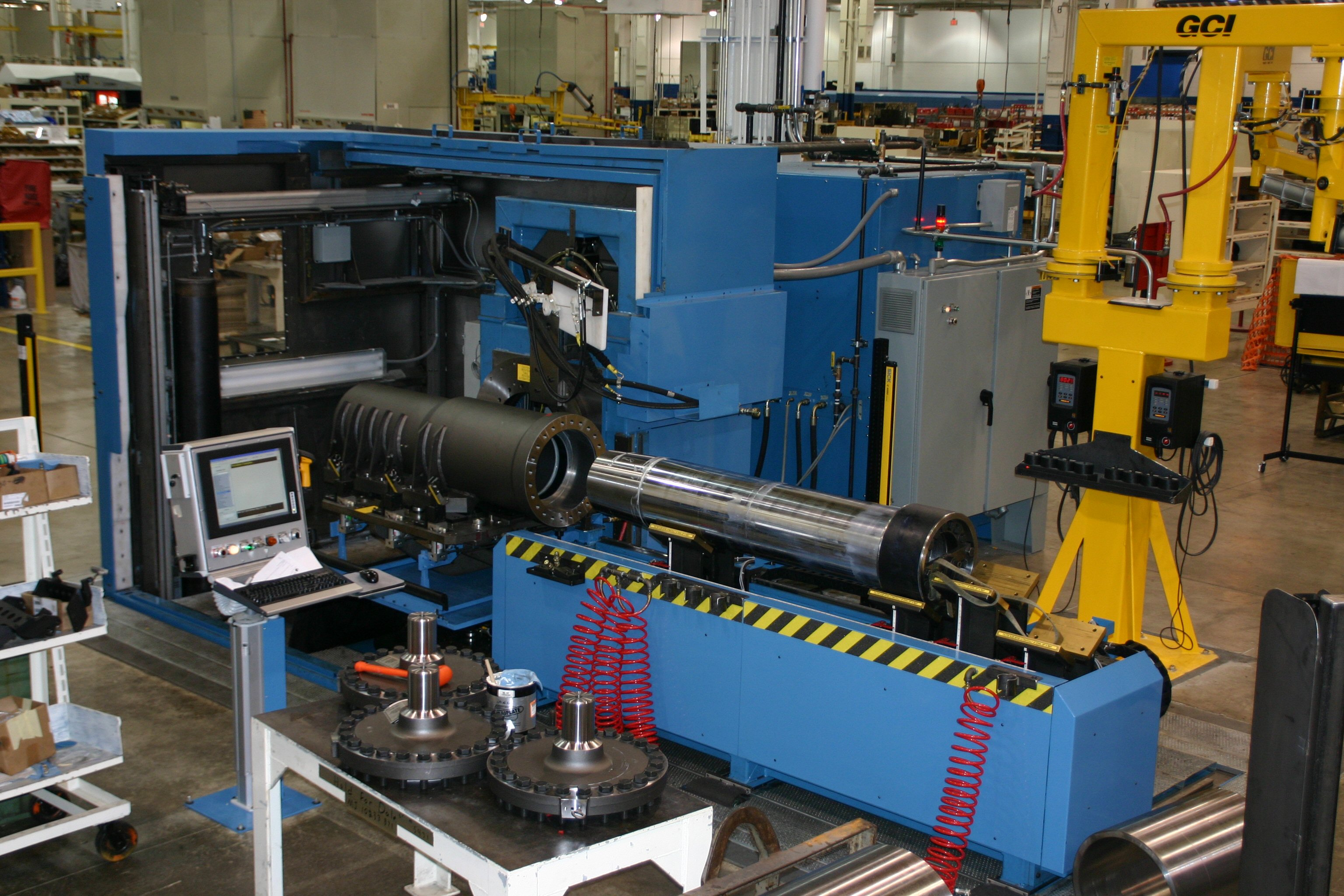

Our founder has been involved with dozens of assembly automation projects throughout his career. We provide expertise in the development of automated assembly systems and assembly processes.

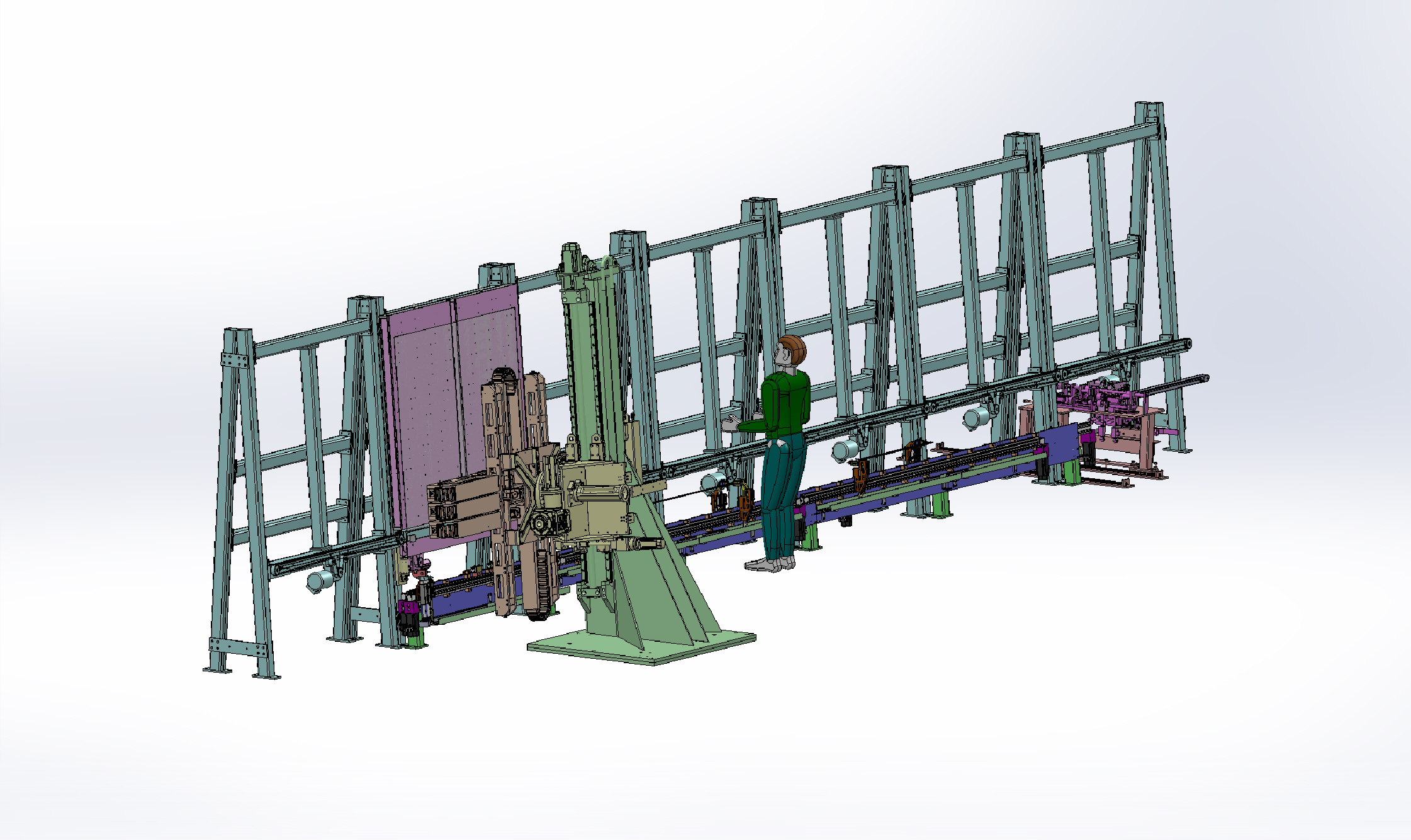

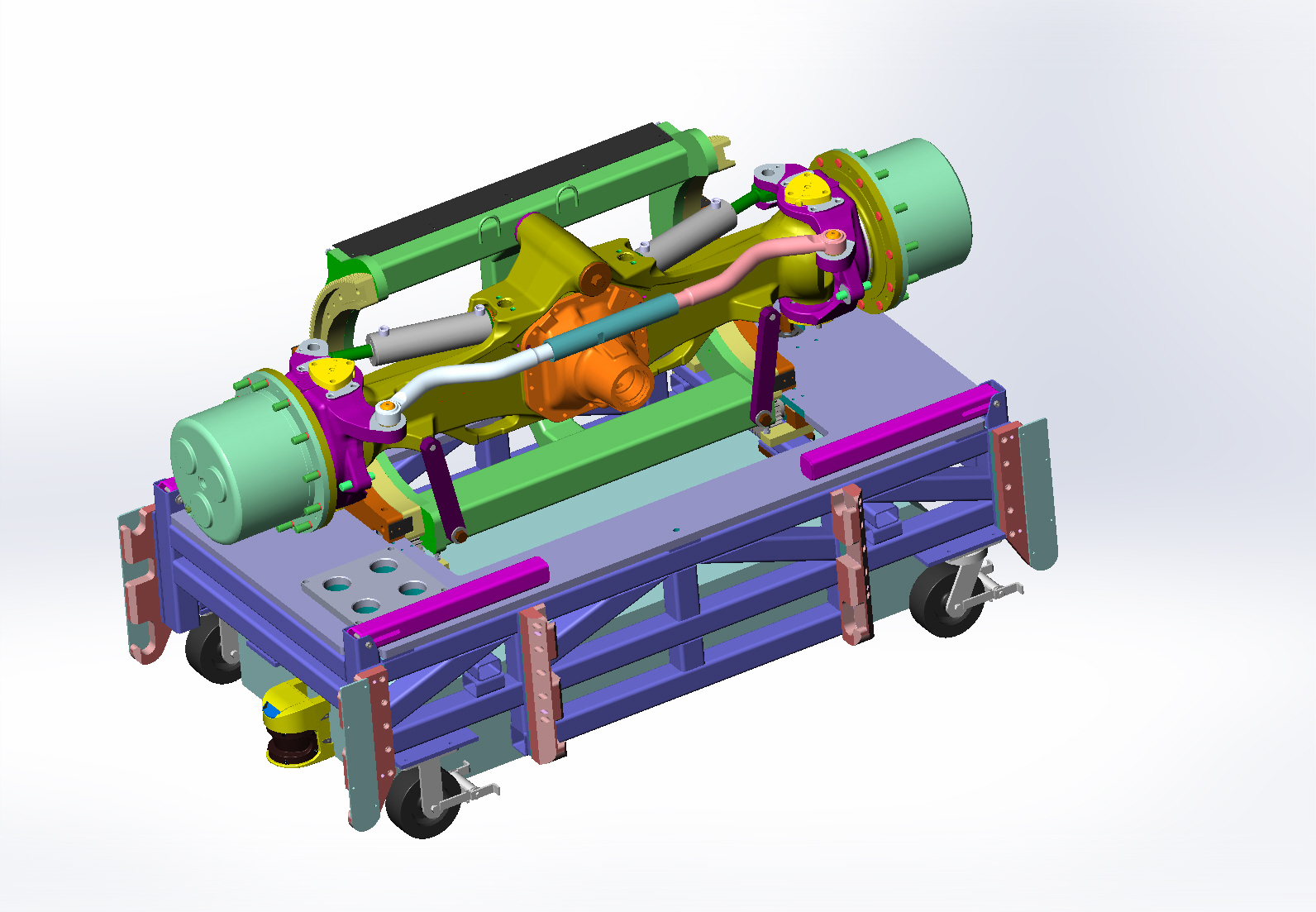

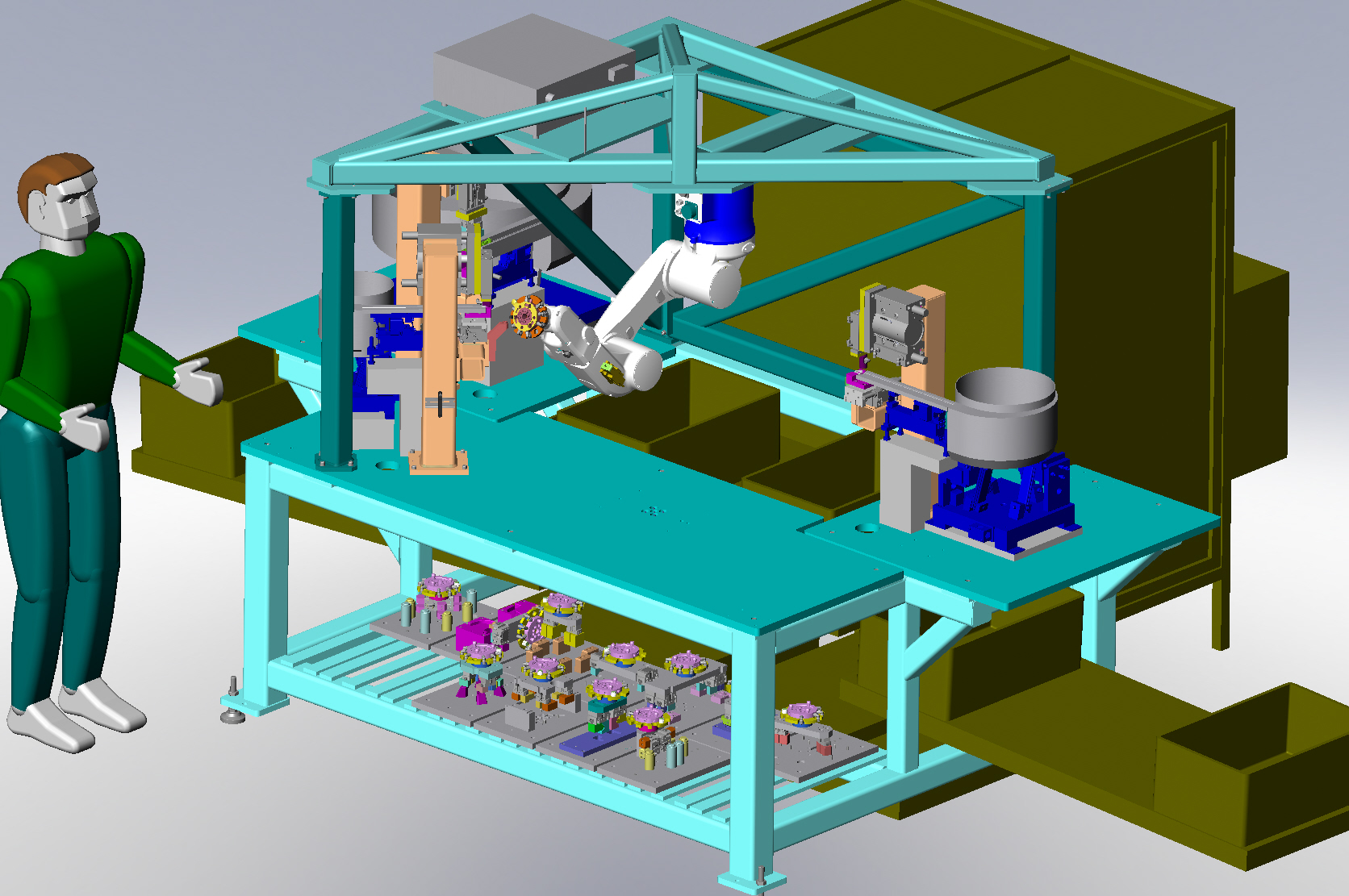

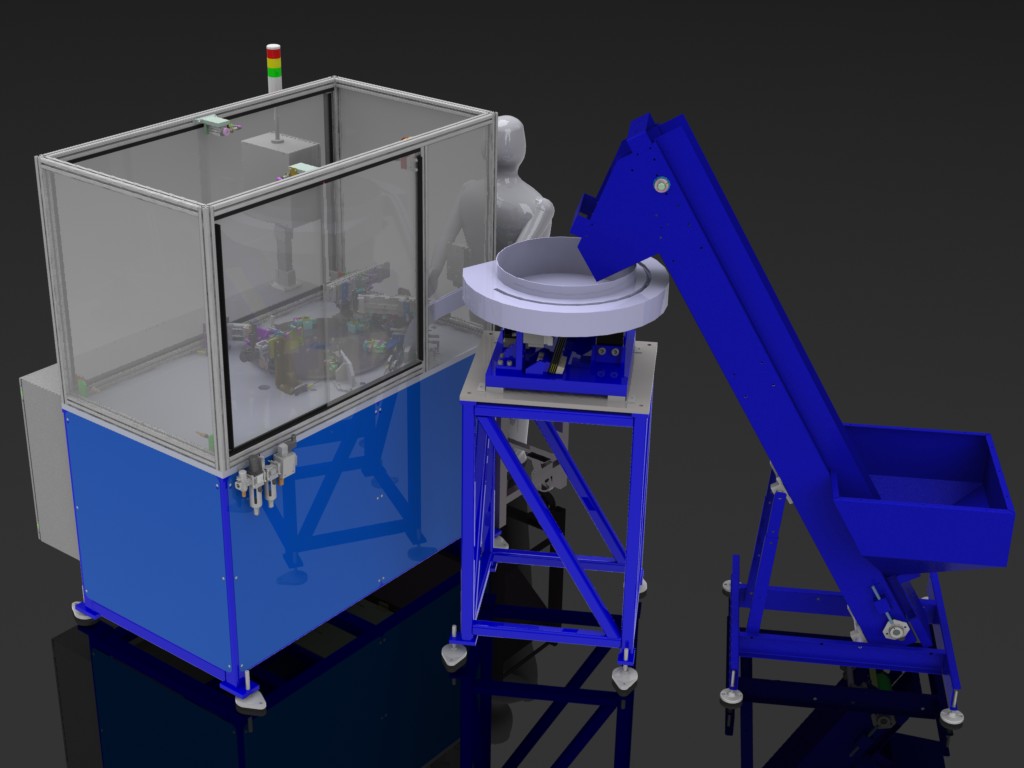

Please review our collection of sample projects below.

Client Comments

Paul’s innovative R&D developments at Gilman provided a competitive advantage for winning new business. His engineering expertise and comprehensive knowledge of automation combined with fresh, creative approaches to problems can benefit any challenge.

very creative… talented in a wide range of fields… reasonable to work with… responsible for one of the most amazing automation systems I’ve ever seen