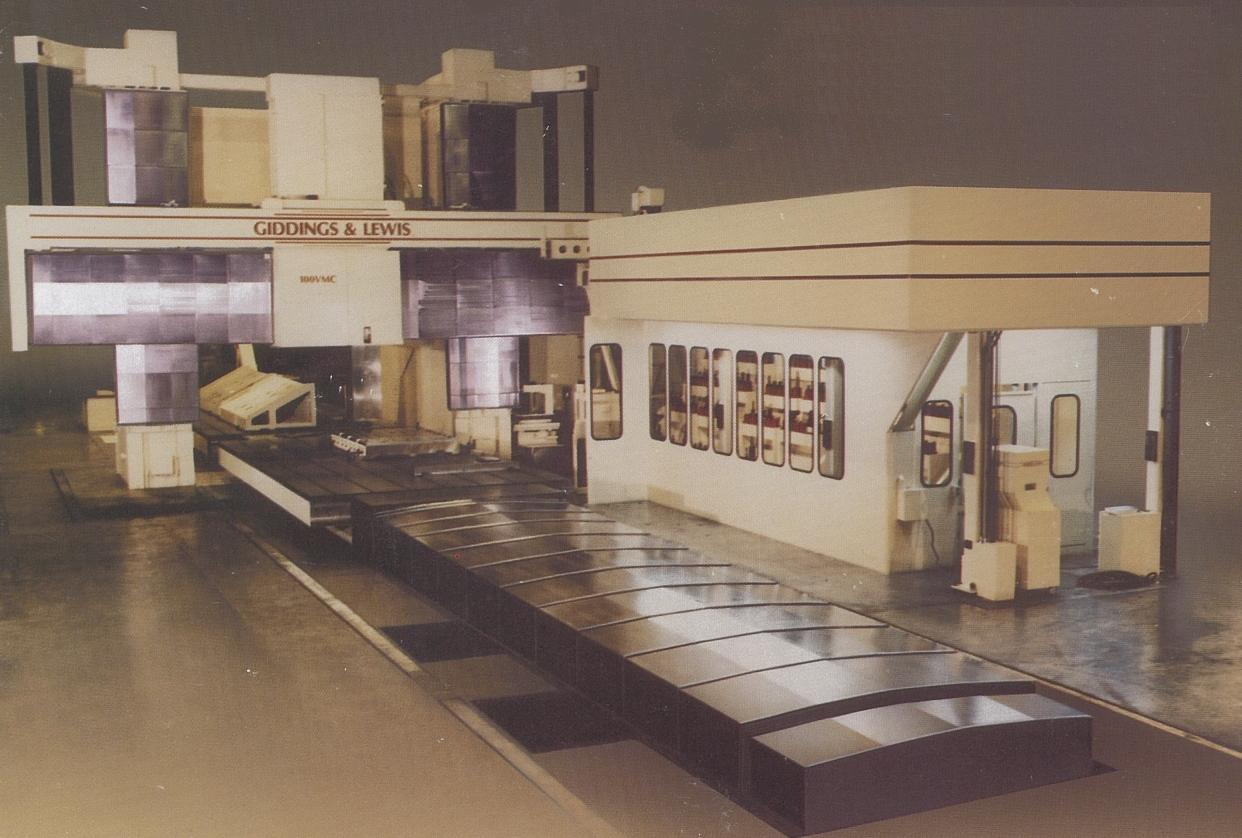

The challenge was to create a tool changer for a machine tool (planer mill) that utilized cutting tools up to 16 inches in diameter and weighing up to 125 pounds. The customer also required that these cutting tools to be exchanged in banks, or groups, that were pre-configured for the part being manufactured as well as minimal tool exchange time. In addition, tools needed to be loaded to the machine tool in either a vertical or horizontal attitude.

The solution was to a large gantry (X, Y, Z) robot capable of handling two of the large cutting tools. The robot’s tooling was capable of rotating each cutting tool taper up or taper horizontal, for loading into the machine tool, as well as taper down, for storage. In addition, the tooling rotated 90 degrees about the vertical axis to provide access to the tool storage racks. Interchangeable tool storage racks were also created that provided a stair-step configuration that allowed different length tools to be stored at different levels without limiting access to the cutting tools on other levels. When the machine tool called for a new cutting tool, the robot would move to the proper storage rack and retrieve the proper cutting tool. It would then move to the machine tool and remove the old cutting tool from the machine tool spindle and place the new cutting tool into the spindle. The old cutting tool was then placed into proper storage rack. An RF tag was imbedded into each cutting tool and each storage rack to insure that the right cutting tool was used at all times.