The challenge was to extend the life of a 35+ year old machine tool. The control hardware was no longer supported and failures were becoming more common. After servicing the machine for more than four years it was finally impossible to find replacement components.

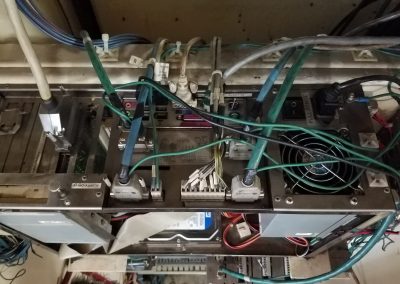

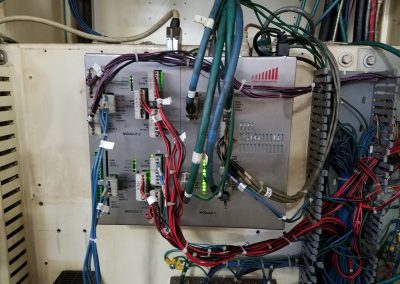

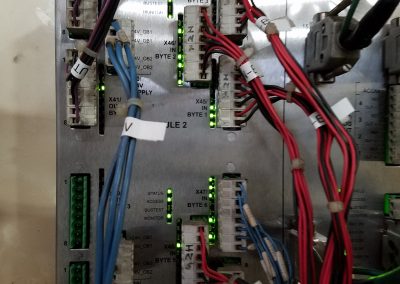

It was agreed that the long-term solution was to replace both the controller and servo drives of the large boring bar. Replacing the CNC controller with a newer version was relatively straightforward with a minimum of software changes required. After much research new servo drives were found that would work with the very old servo motors. Repair services for the servo motors were also located for the customer.