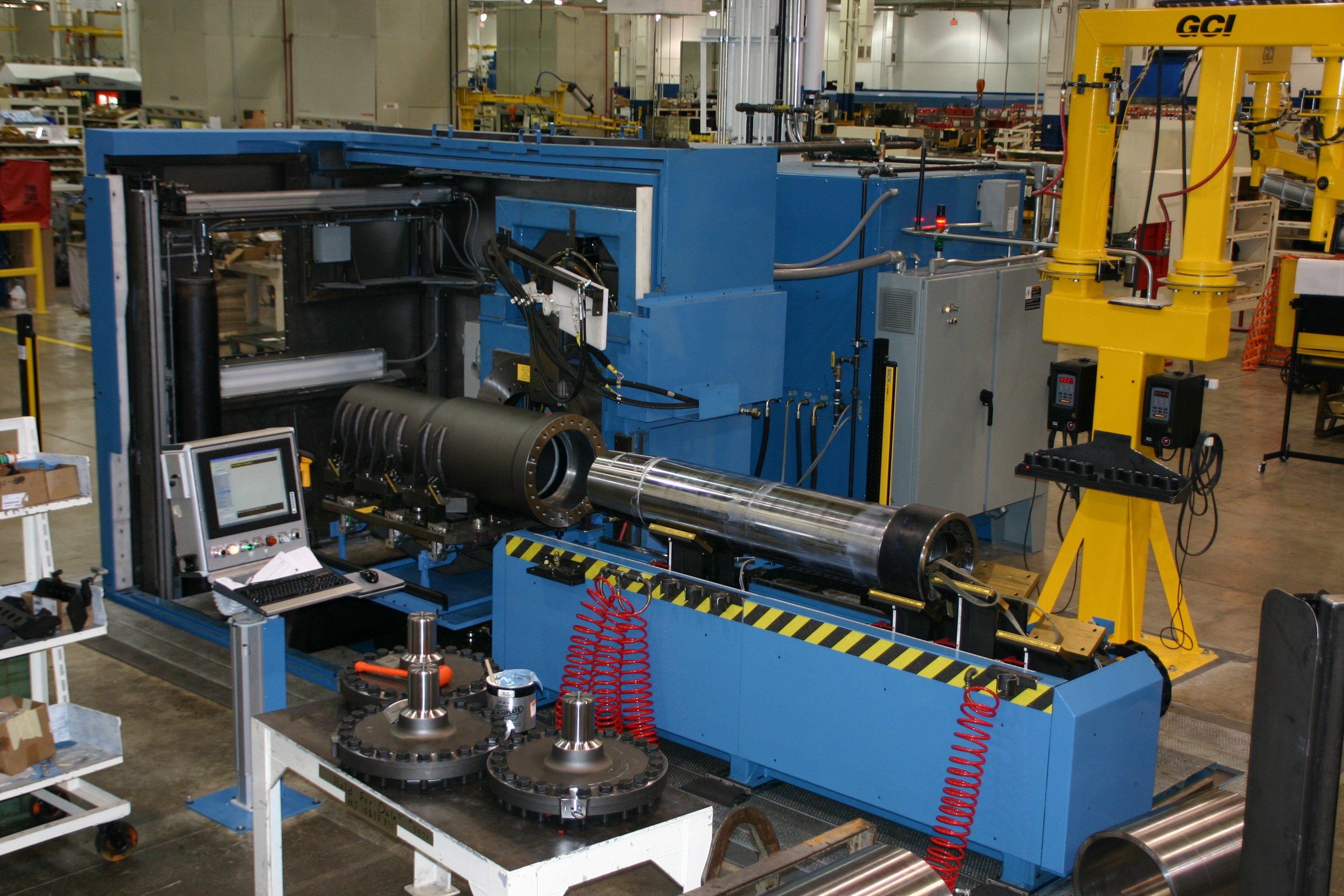

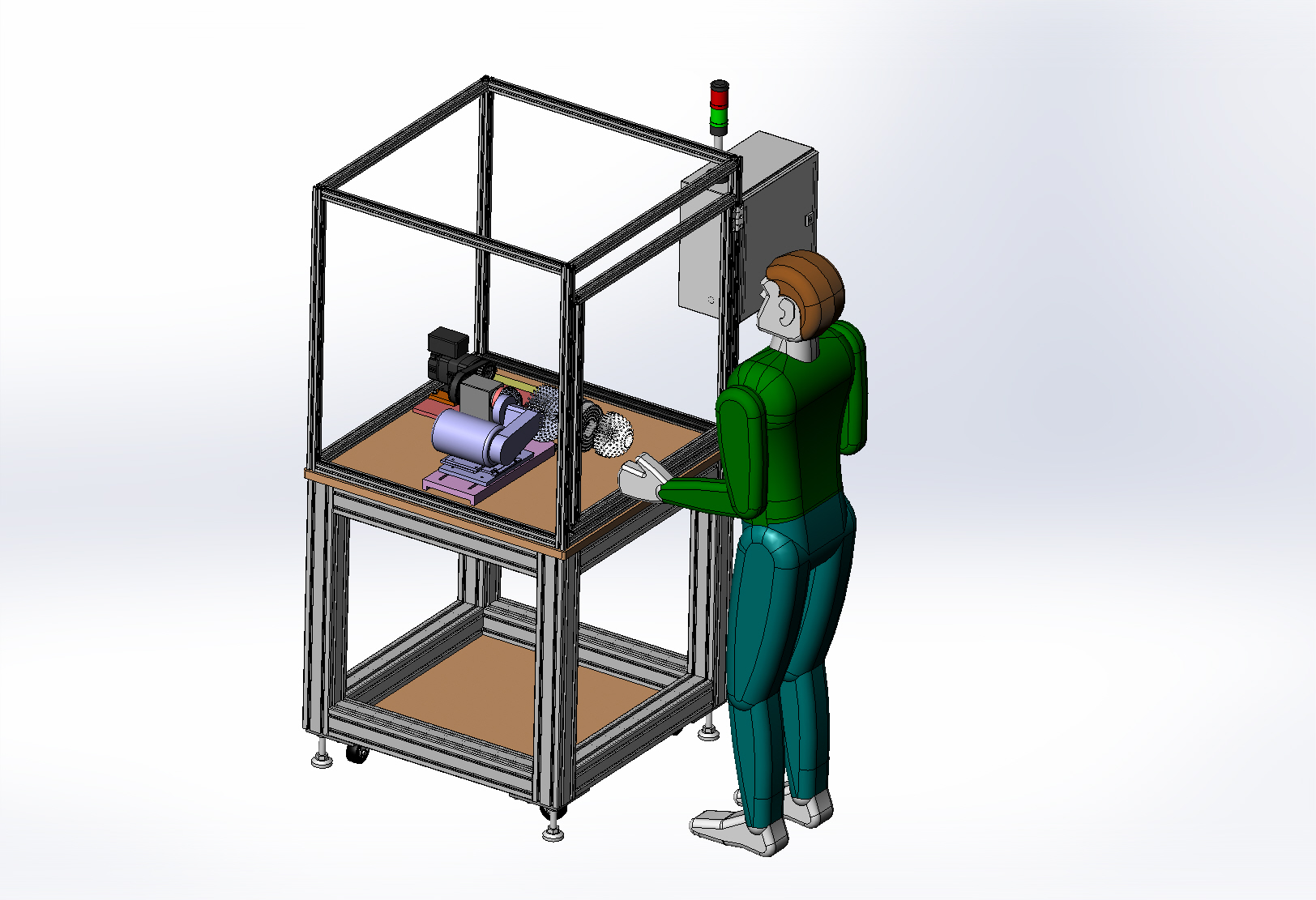

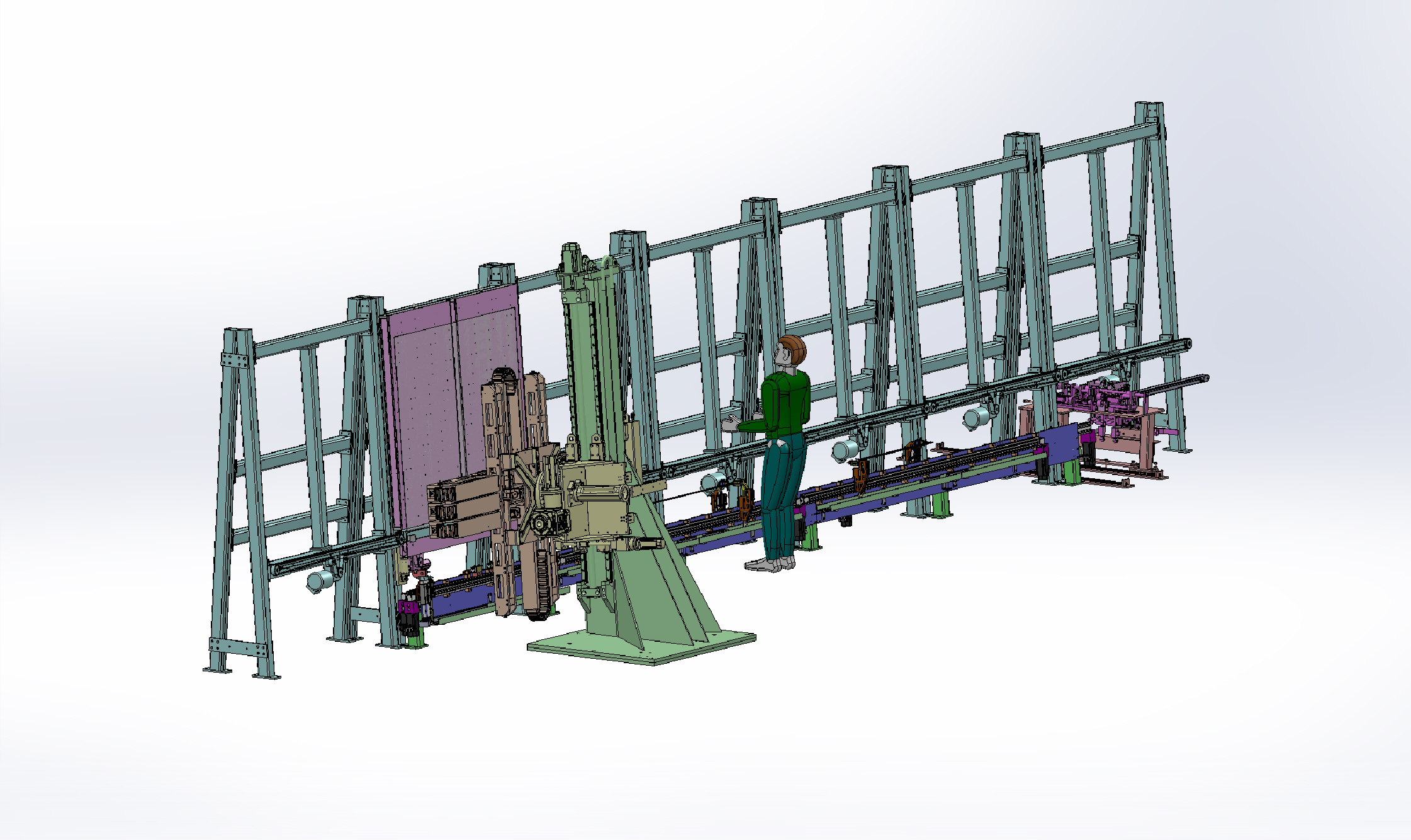

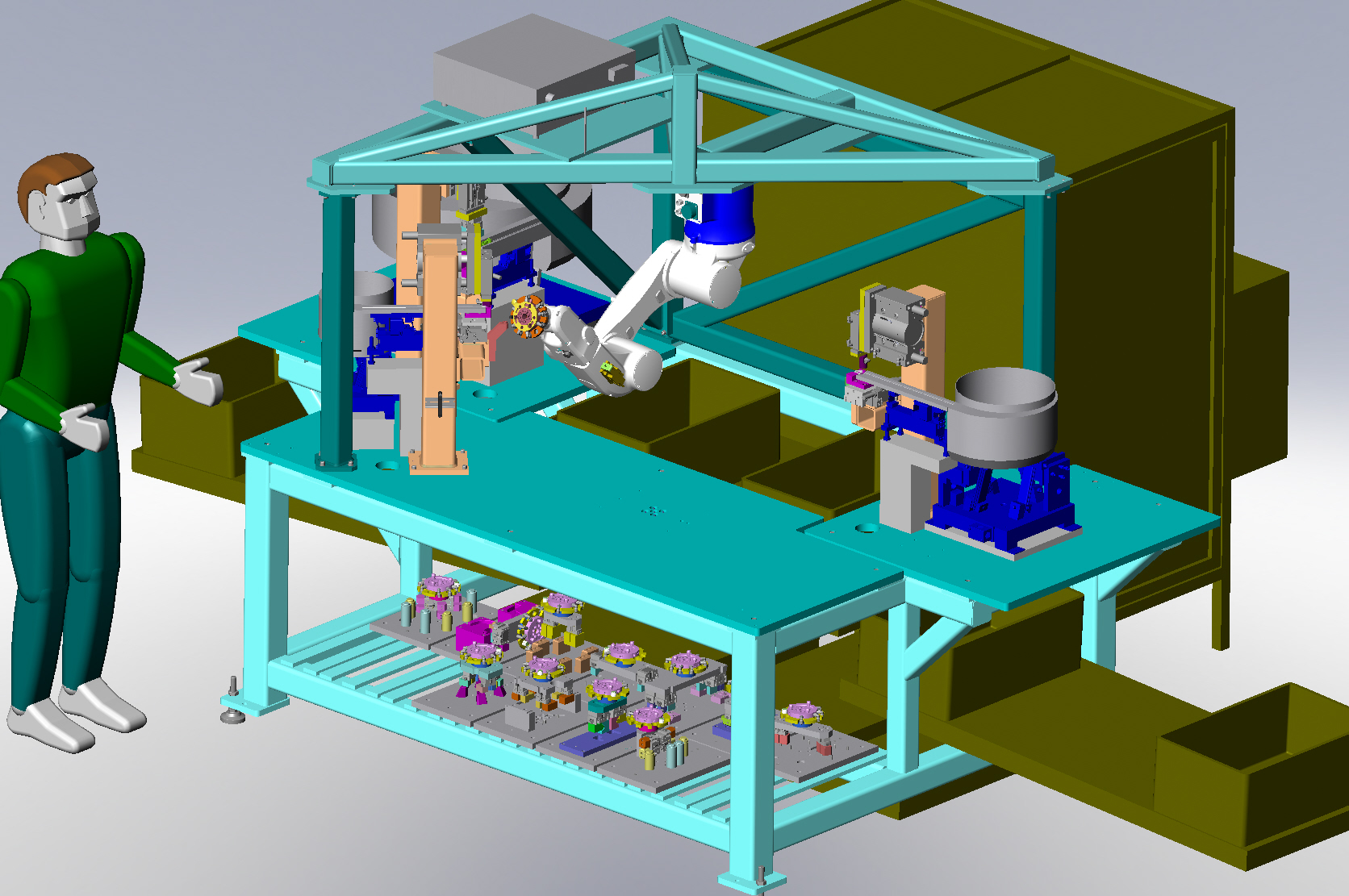

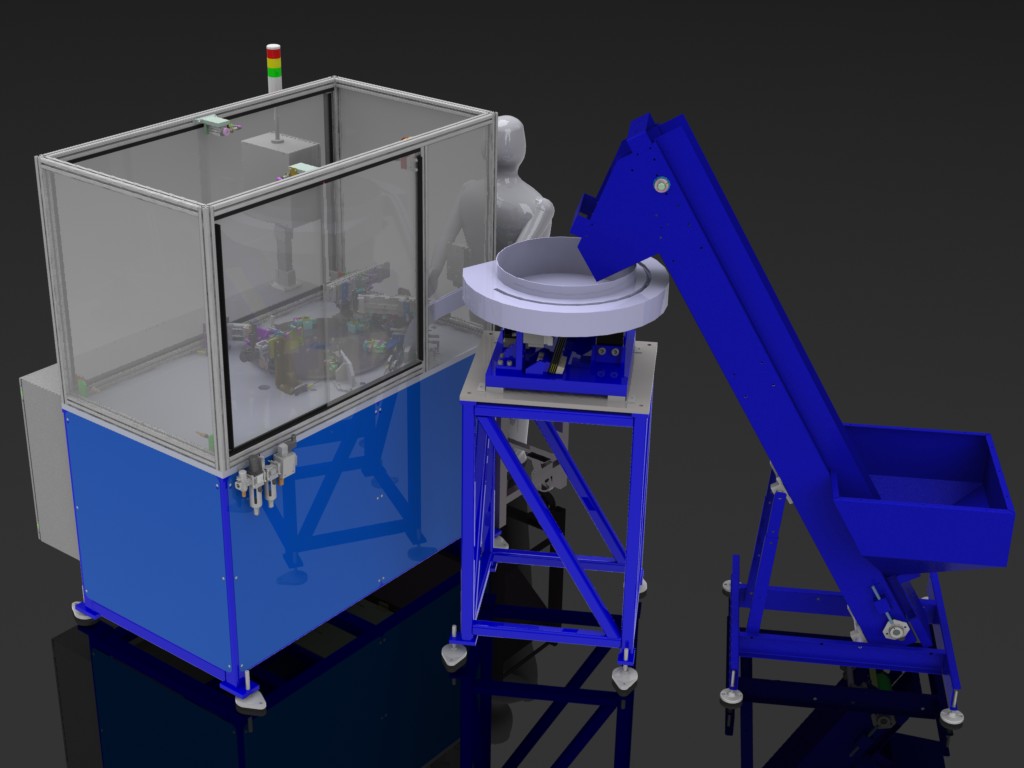

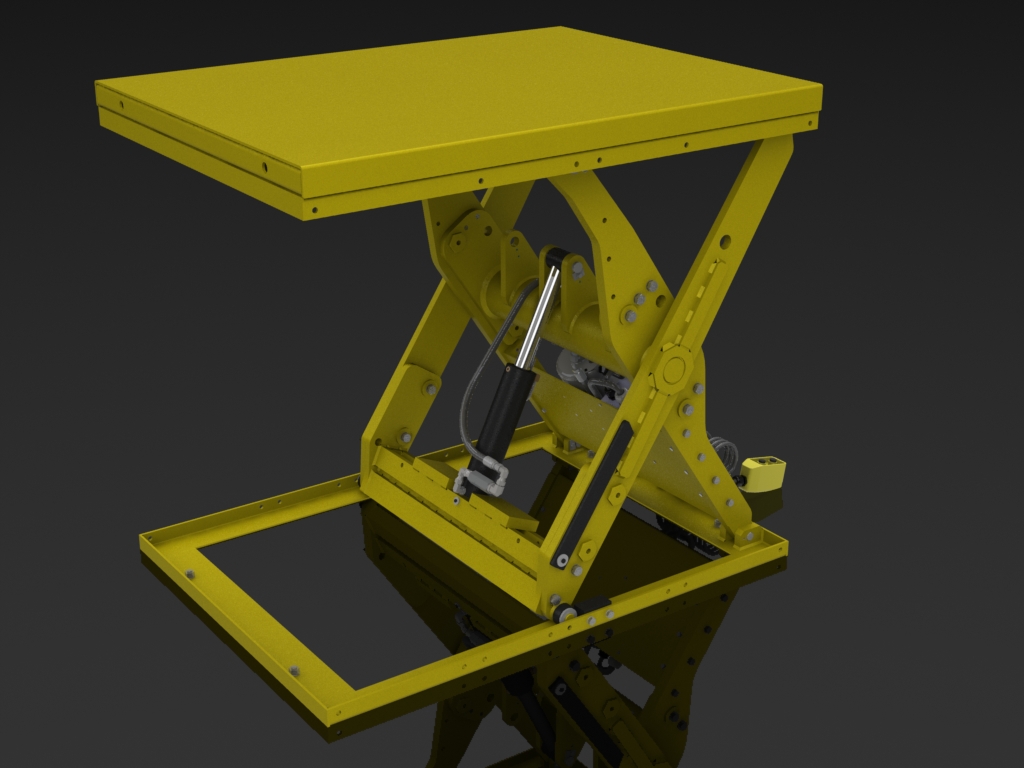

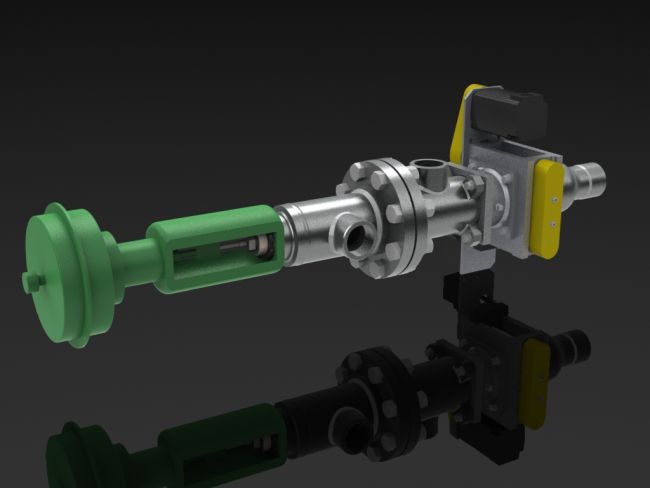

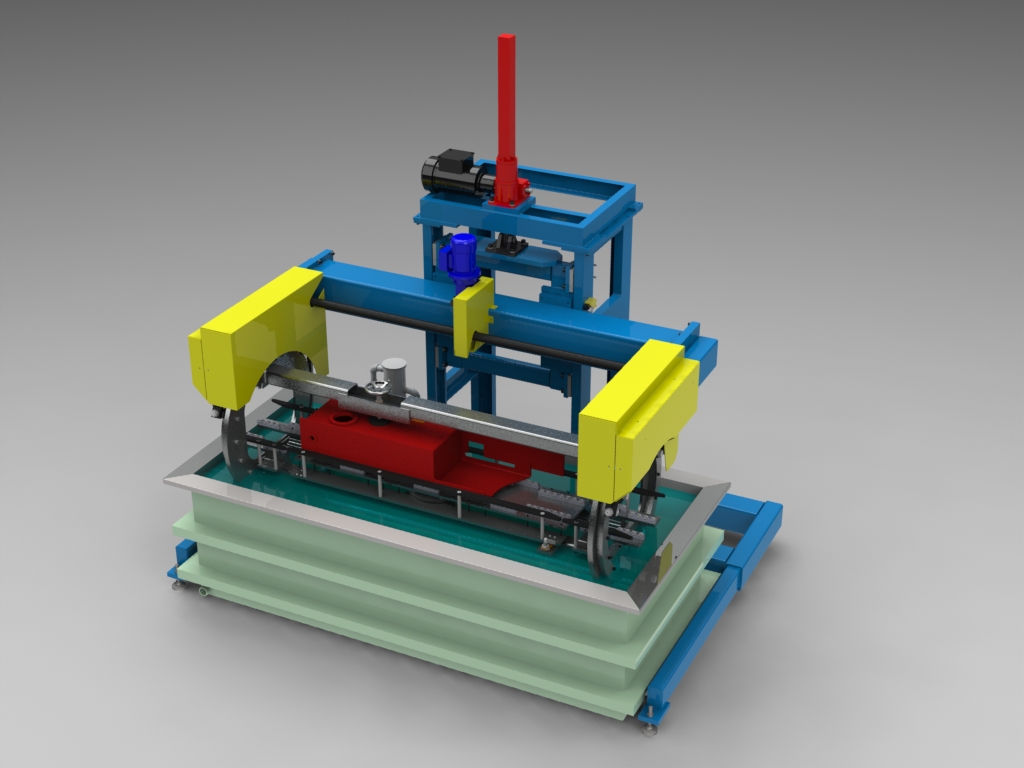

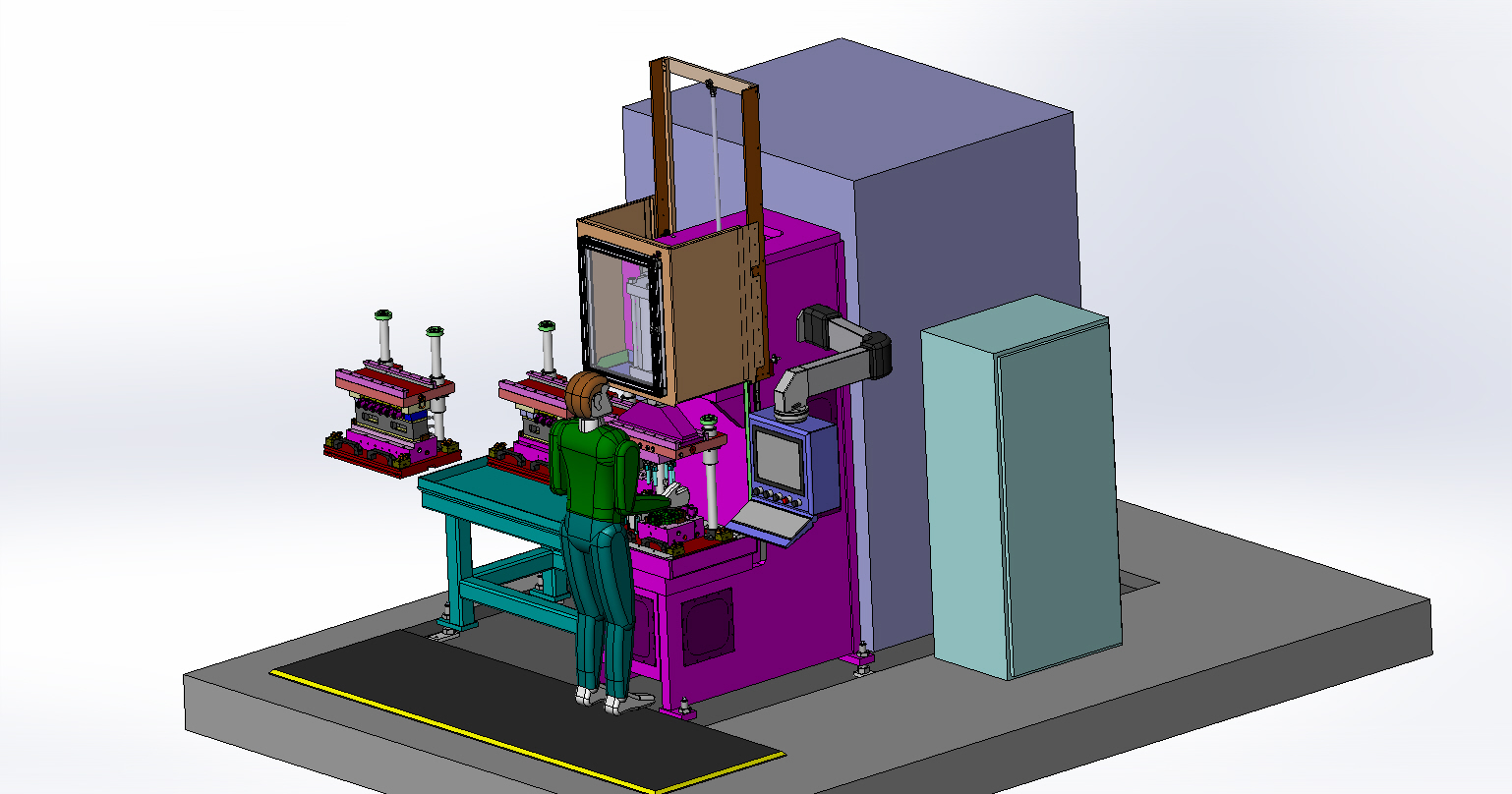

Industrial Equipment

Innalytical Solutions provides consulting services relating to all types of automated industrial equipment. We can provide expertise for your new design project, troubleshooting efforts, failure analysis, or machinery upgrade projects.

Our principal has been involved with dozens of different pieces of industrial equipment throughout his career.

Please review our collection of sample projects below.

Client Comments

Innalytical Solutions is a powerhouse of industrial knowledge. It is rare to find an engineering house that can efficiently incorporate the latest technological solutions in all the stages of automation including controls, motors, software, communications, tooling, machine structure and product innovation across a myriad of markets. I highly recommend Innalytical Solutions to anyone wishing to enhance their product or achieve a leaner manufacturing system. Paul has never ceased to amaze me on his engineering prowess and innovation when it comes to meeting a difficult product or automation challenge. I’ve seen him do the impossible in order to reduce manufacturing costs and enhance product quality, much to the dismay of his customer’s competition.

Paul has been instrumental in managing both mechanical and servo driven engineering requirements at Titan. His designs have proven to be rock solid. More importantly, our customers have developed a long track record of satisfaction with his work.