Our customer was faced with a significant hurdle. Their sensor system was not allowed in certain European countries because of concerns for its safety. The sensor, used widely in the United States, was mounted to the roof of a station wagon and driven down streets and highways while data was being collected. The concern was that the weight of the sensor exceeded the rated roof rack capacity of the automobile manufacturer.

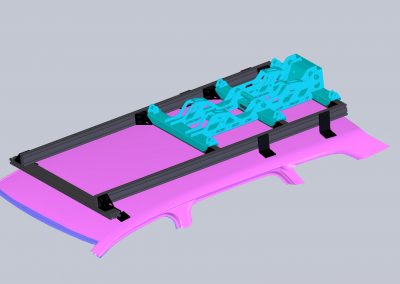

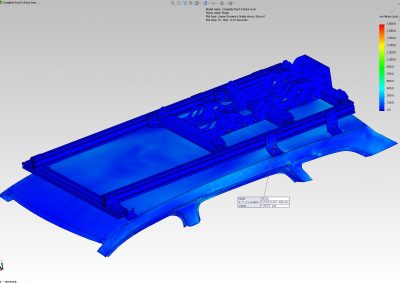

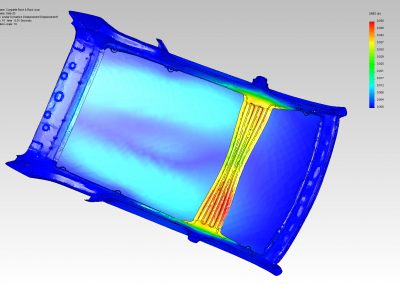

The solution was to provide a thorough Finite Element Analysis of the sensor and its support structure mounted to the automobile roof. The combined assembly was subjected to dynamic loads of up to 60 Gs to determine the stresses placed upon the individual components.

As a CAD model of the automobile was not made available, a model of the automobile roof was generated using a 3D laser scan of an actual automobile. This model was then used to complete the analysis.